The Need for Supply Chain 4.0

Click to zoom in

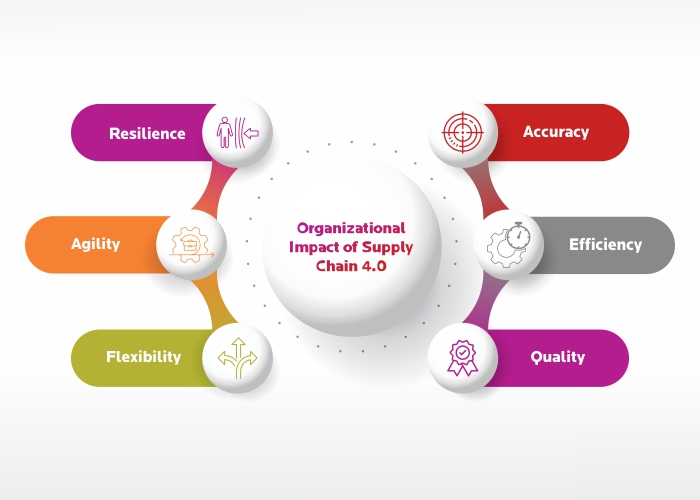

Supply Chain 4.0 Impact

Impact of this radical Supply Chain 4.0 is felt across the entire operations.

Supply Chain 4.0 is a value addition when inculcated properly in the various aspects of supply chain management. Following are the various ways in which the new technology influences the entire system:

Resilience

Increasing resilience is a priority now for the majority of businesses as they emerge from the current crisis. According to a

Gartner survey, 21% of the respondents have stated that they are already equipped with a highly resilient network today. The retaining cost of supply chains in multiple locations will be seen as the cost of doing business, rather than inefficiency. Strategies such as dual sourcing, alternative factories, generous safety stocks do go against the lean supply chain models, however, rebalance between resilience and efficiency must be achieved for better functioning.

Agility

Upgraded and new approaches of product distribution reduce the delivery time of the high performers and heavy machinery by a few hours. The foundation of these services is advanced forecasting data and approaches, e.g., predictive internal demand analytics, external market trends, construction metrics, weather conditions etc. These forecasts are carried out on a monthly basis and dives deeper into the customer demand and machine status data for improving overall operations and productivity. Forecasts are carried out faster for faster-moving logistics, every day. The future holds the door to predictive shipping. Processes are made agile, and the swiftness is felt across all the departments and workflows aligned to shifting customer expectations.

Flexibility

Makeshift and real-time planning permeates a flexible response to changing demand or supply scenarios. Planning becomes a consistent process. Planning cycles and freeze periods are reduced subject to changing needs or constraints. Once the products are out for delivery, coherence and flexibility are ensured throughout the process till shipments are reached to customers in the most convenient manner.

New business frameworks such as Supply Chain as a Service for planning, functions or transport management, fine tunes the flexibility of the operations allowing the organizations to create both economies of scale and scope along with fascinating outsourcing opportunities. For instance, crowd-sourced and flexible “Uberization” of transport significantly step up the agile distribution networks.

Accuracy

The next-gen Supply Chain 4.0 provides real-time, end-to-end openness and transparency throughout the supply chain. The scope of information travels from top-level KPIs, such as overall service level, to the granular level process data, such as determining the exact location of vehicles in the network. The data range offers a clear view of information based on all levels of seniority and processes in the supply chain. All the stakeholders operating in the same cloud are integrated, and the same outcomes are delivered across the nexus.

With the help of a high-performing digital supply chain management, targets are set automatically using clean-sheet models. In case of digital disruptions, having a realistic target and aspiring to achieve one set the bar. Performance management system intervenes here. Automatically identify risks and exceptions to change the supply chain parameters, accordingly mitigating the risks and enabling a process to ace these targets.

Organizational Impact of Supply Chain 4.0

Click to zoom in

Efficiency

Automation of both planning and physical tasks augments the efficiency of a supply chain. Intelligent automation handles the complete warehousing operations – from receiving or unloading to pack, ship, and deliver consignments. Optimizing transports and truck utilization increasing the flexibility and efficiency of the entire transport system. Cross-company transport optimization is applied to capacity sharing between enterprises. Putting together the entire network in place and continuous optimization ensures enhanced efficiency.

Quality

Consumers demand more personalized products, and the need for them is continuously increasing. Thus, micro-segmentation and mass customization are strongly focused on for the final implementation of ideas. With it comes the need to look into the product quality. Customers are identified and segregated into small clusters. A broad range of products and offerings are identified suitable to their needs, and finally comes the entire process of quality checks. Checks are put across the various endpoints to ensure higher quality.

Process automation ensures quality measures against set benchmarks, quality control, and revisiting the journey in case of degradation in the outcomes.

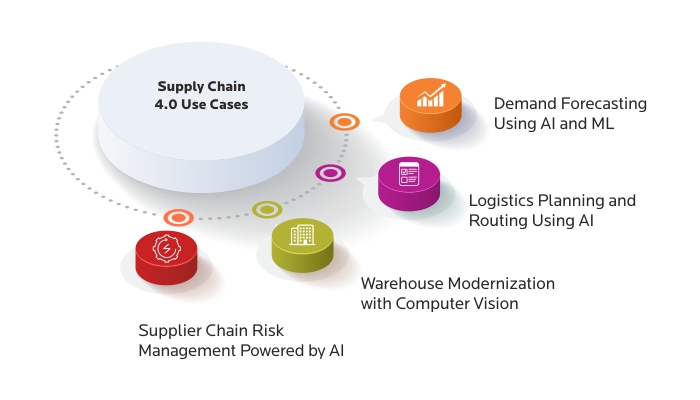

Use Cases of Supply Chain 4.0

With the new technology revolutionizing the supply chain operations, through the advanced technological adoptions, it is finding a number of use cases in the industry. Following are some of the application areas innovated leveraging on the technological intervention.

Demand Forecasting Using AI and ML

Before we dive deeper into how Artificial Intelligence (AI) and Machine Learning (ML) are changing the very face of demand forecasting, let’s understand there are two variables to depend on while running the forecast for an SKU –

- Sales volume

- Demand volatility

The combination of the two defines the kind of model needed for precision in demand forecasting. Research says that businesses can reduce their

planned inventory by 2.5% if the inventory forecast is improved by 1%.

The basics necessary to build the right model is the right data set and follows the following three-step process:

Detection and treatment of outliers crucial for creating a stable AI and ML model. Statistical information such as inter-quartile range detection and box plotting are the most common approaches. Using these approaches, high fluctuations in data are brought under control that occurs due to outliers.

Carving the machine learning model based on the outcome of the outlier detection treatment. Exploratory data analysis is done to identify patterns and trends. For certain cases, data might not show any trends. For certain other, a predictive analysis model might be a better fit.

The final step is to evaluate the data accuracy of these models through a thorough calculation of Mean Absolute Error or Root Mean Square Error. In a nutshell, the entire demand forecasting process ensures smarter integration and futureproof planning.

Logistics Planning and Routing Using AI

The future sees more automation across the various logistics component such as supply chain, inbound, warehouse management, outbound logistics, intralogistics, and

logistics routing. Highly encouraged by Industry 4.0, Industrial Data Space is one approach adopted by all the major logistics players who are looking towards carving a strong digital future.

Blockchain technology, AI, and the Internet of Things (IoT) are identified by all the major players to automate supply chain management and logistics routing. A core component of Logistics 4.0, an extended arm of Supply Chain 4.0 is faster logistics routing. Enabling semi-autonomous decisions, self-driven vehicles, maintenance of logistical assets, edge computing, fog computing, ensuring multiple logistics use cases, and deploying solutions specific to the case, streamline the entire operation and work processes with limited manual intervention and increased productivity.

Supply Chain 4.0 Use Cases

Click to zoom in

Warehouse Modernization with Computer Vision

The thriving Industry 4.0 technologies – artificial intelligence, internet of things (IoT), predictive analytics, augmented reality, computerized vision, big data, robotic process automation, and digital twins are driving the entire supply chain ecosystem towards Smart Warehousing.

A smart warehouse is a technologically sound framework enabled through workflow automation, sturdy analytics, IoT-driven devices that are put together to streamline inbound logistics, inventory, and outbound logistics. By integrating smart technologies across the warehouse value chain, companies can create a more responsive, efficient, and swift supply chain.

According to some reports, the smart

warehouse market would be significant for the new future and will generate 19 billion USD in revenue by 2025. The next decade will witness a revamp of the entire warehousing operations with manually driven activities switching gears towards next-gen technologies. Aim would be to make inventory management more visible, improve accuracy, reduce manual intervention, minimize the total cost of ownership (TCO), and giving a leg up to operational efficiency.

Supplier Chain Risk Management Powered by AI

Enterprises need to design better ways to deal with

supplier risk management in today’s fast-moving and volatile world. Unable to gauge the liability the organizations are carrying gives a blow to the operations. Gartner research report states that 53% of the organizations adopt a reactive approach when it comes to supplier risk management. A weak supplier risk assessment might have something beyond commercial repercussions. The need of the hour? AI-driven smart solutions to encourage agile and enhanced decision-making through course corrections and better visibility into the supplier networks.

AI designs are data-driven and real-time methodology to communicate with the suppliers. These smart solutions reduce operational downtime, and organizations are informed in advance if there’s a shortage of raw materials. Minimizing production downtime, enterprises meet order completion rates, adding value to customer experience. Access to real-time information from multiple sources, including non-traditional, helps these entities to better prepare and handle any non-compliance issues safeguarding reputation and operations, alike.

Organizations minimize their dependency on emergency purchases from moderate to high-risk profile suppliers. Potential supplier disruptions help organizations to spread their risk and reduce the aftermath. AI-based solutions are staying above manual tracking to reduce processing costs per order with better monitoring and assessment.

The Future of Digital Supply Chain

Supply chain 4.0 is already here! The traditional framework and work processes that we were accustomed to are slowly disrupted and reinvented to suit the current needs. While the organizations are still in the developing stage, most of them have started exploring possibilities of smart solutions into supply chain and logistics.

The time needs businesses to move faster and be the torchbearer of the shifts taking place in the enterprise landscape. The journey ahead is one of the automated work processes and integrated solutions. Various logistics components such as supply chain, inbound, warehouse management, intralogistics, line feeding, outbound, and routing are all revisited on new technological grounds.

Intelligent automation, Internet of Things (IoT), predictive analytics, advanced robotics, big data, and more technological innovations are altering the journey of the supply chain industry every day. The industry is going through constant upgradation. These Industry 4.0 trends can cull out huge benefits to business operations. They do have their own set of integration challenges and disruptions, however, they offer a leg up to the entire supply chain process.

Aiming for faster delivering and optimizing time? Predictive shipping is the way out. Already big brands like Amazon hold a patent and practice predictive shipping. Matching the customer order to a shipment at a later date, order is shipped before it has even been placed. This ensures product availability already in the logistics network, in transit to the customer location.

Cognitive Cloud Technology enables better stock replenishment decisions by offering increased visibility of the entire supply chain operations. It takes into consideration the market volatility and supports comprehensive planning. Ensure greater monitoring and optimization through cognitive insights.

If modernization and technological intervention happens seamlessly across the processes, the supply chain paints a highly autonomous, agile, and predictive picture in its stage of maturity.

Key Takeaways

Therefore, to embrace Supply Chain 4.0 it is essential to create a roadmap that is aligned with your business goals. Be it traditional approaches or a fresh technological revolution; unless it fits right with your business goals, it will fail to take businesses a step closer to their expected outcomes. So the major highlights to keep in mind while integrating a smart supply chain solution:

Define the Supply Chain 4.0 roadmap for your organization. Take into consideration how digital is shaping up your key logistics priorities, data-driven supply chain decisions and their impact on your overall business operations, applications that deliver the value and fund the journey, and encouraging experimenting and pilot projects before the final launch.

Account for the cultural challenges and shifts. If not addressed at the right time, this could act as the major roadblock to successful integration. Align the stakeholders on the highest levels with the necessity of the analytics and sophisticated data science capabilities, ML and AI solutions, and how their integration is going to pan out, impacting the entire operations.